Drinking water quality regulation and PVC: safety get the facts

admin October 17, 2023 0

Drinking Water Quality

In the United States, the safety of drinking water has been traditionally ensured by testing it at the source (reservoirs, rivers, groundwater). However, once water leaves these sources, travels through pipes, and reaches our homes, it is typically not tested. The recent discovery of unsafe lead levels in drinking water across the country has raised concerns about the adequacy of source testing. If a home was built before 1940, the service line likely contains lead, which poses health risks.

Congress allocated $15 billion to replace lead service lines, but there’s no guidance on what materials to use.

Plastic pipes are often promoted as an alternative, but their safety is a concern. The replacement of lead service lines primarily incurs costs for machinery and labor, not the replacement piping material. Copper, for instance, raises the total project price by about 5%.

The National Sanitation Foundation certifies plastic pipes, partially funded by manufacturers, relying on self-reported data, which raises questions about independence.

Industry self-regulation may not ensure public safety, and independent examination of published literature raises concerns about using plastic pipes. Replacing lead service lines with plastic pipes could potentially create new problems without adequate oversight. The public should play a role in deciding which pipes are used, given the billions in federal and state funding allocated for these replacements.

Replacing lead service lines with safer pipe materials is crucial for public health, as lead-contaminated drinking water can lead to severe health issues, particularly in children and adults. The Bipartisan Infrastructure Deal, signed into law in November 2021, allocates $15 billion for lead service line replacement. However, the U.S. Environmental Protection Agency (EPA) offers no guidance on choosing safer piping materials, leaving communities to decide among options like metal pipes (e.g., copper) and plastic pipes (e.g., PVC or HDPE).

All water pipes can release chemicals into drinking water, and plastic pipes release more contaminants than unlined metal pipes. Communities need to understand potential health risks associated with different pipe materials to avoid “regrettable substitutions.” This report specifically examines the health risks associated with PVC and CPVC pipes, which are common choices for service lines. PVC’s production involves harmful chemicals, with exposure linked to various health risks.

Chemicals can leach into tap water from PVC and CPVC pipe walls, fittings, gaskets, and cements, posing health risks and necessitating further study. The production and transportation of PVC pipes can release harmful chemicals into the air and water, leading to environmental concerns.

While focusing on the health risks to consumers using water delivered by PVC or CPVC pipes, the report touches on dangers at other stages of the product’s life, including manufacturing and transport. It does not comprehensively compare pipe materials but encourages communities to choose safe water pipe products.

Dr. Terry Collins, Director of the Institute for Green Science, emphasizes the importance of ensuring the replacement process does not result in further harm, stating that contaminant leaching from plastic piping could lead to disastrous consequences.

Key Findings:

1. Independent research has identified up to 50 toxic chemicals released by PVC and CPVC pipes into drinking water. The number of chemicals released can vary due to different product formulations and pipe brands, making it challenging to determine precise figures. Research on this issue is limited, with government agencies not conducting such research, leaving it to independent researchers to secure funding for this crucial work.

2. There is a lack of data on chemical releases from PVC and CPVC pipes in real-world settings. Most studies have been conducted in laboratory settings, making it difficult to relate findings to in-service water pipes. Further research is needed to understand liberated chemicals’ nature, liberation processes, pipe stability, and water variable influences.

3. PVC and CPVC pipes release hormone-disrupting chemicals, including organotins and potentially phthalates, which can cause health issues, particularly in children and fetuses. Exposure to these chemicals raises concerns about the safety of water delivered through such pipes, and the EPA lacks legal drinking water exposure limits for organotins.

4. Vinyl chloride may be released into drinking water from PVC and CPVC pipes at levels below the EPA’s legal safe drinking water limit but at levels of potential health concern. Accumulation in stagnant water and possible creation as a disinfection byproduct are concerns. Routine testing for vinyl chloride in tap water is not required by EPA standards.

5. Existing drinking water quality regulation standards do not provide sufficient protection for the public’s health. Standards for synthetic chemicals, like those released by plastic pipes, apply at the water treatment plant, not at the tap. Public safety relies on standards set by a private organization not accountable to the public, and cumulative exposure to chemical mixtures in water and the environment is not factored in.

6. PVC and CPVC pipes can release more hazardous chemicals into public water supplies when they burn, as in wildfires. This includes cancer-causing benzene and styrene at levels exceeding EPA health-risk guidelines. After wildfires, communities may lose access to safe drinking water due to the melting or burning of PVC and CPVC service lines.

7. PVC manufacturing and transportation release toxic chemicals, including cancer-causing vinyl chloride and dioxins, into nearby communities. Low-income communities and communities of color bear the disproportionate burden of this pollution. Other hazardous chemicals used in PVC production include chlorine gas, ethylene dichloride, and often asbestos, PFAS, or mercury.

Recommendations:

As local and state officials and the public proceed with replacing lead service lines, it is crucial to address key questions and considerations:

1. Pipe Material: Determine the material of the replacement pipe. Consider alternatives to PVC and CPVC.

2. Chemical Data: Seek information on the chemicals identified and their levels in certification testing, which have been found to leach from the pipes.

3. Pipe Liners: Assess whether the replacement pipe includes a liner. Avoid liners that may contain bisphenols or plastic materials, which are often endocrine disruptors.

4. Copper Alternatives: If considering copper piping as a safer alternative, check if recycled copper is available. Consider using recycled copper piping if it’s an option due to potential environmental impacts associated with copper mining and smelting.

5. Project Costs: Review the breakdown of project costs, including machinery, labor, construction expenses, and the costs associated with various replacement piping options. Note that the cost of replacement piping, regardless of the type used, typically represents a smaller portion of most lead service line replacement projects.

These recommendations are essential for informed decision-making during lead service line replacement projects.

Plastic Water Pipes 101:

Plastic water pipes emerged in the 1950s as alternatives to traditional materials such as lead, iron, steel, asbestos cement, and vitrified clay. Plastic pipes were considered less prone to corrosion and more durable than metal pipes, which typically have a lifespan of about 50 years. Remarkably, lead pipes were not banned by the EPA until 1986, despite their well-known toxic effects.

– PVC Pipes: PVC pipes were the first plastic pipes introduced and now dominate new water and sewer installations due to their cost-effectiveness. These pipes are rigid and durable but can be damaged by heat. Chlorinated PVC (CPVC) is a more robust version with added chlorine molecules for higher temperature tolerance and overall resilience.

– Polyethylene Pipes: Polyethylene pipes, including high-density polyethylene (HDPE) and cross-linked polyethylene (PEX), are also used for potable water distribution. HDPE pipes are commonly used for water service lines, while PEX pipes are preferred for indoor plumbing due to their flexibility and fewer connections. PEX can convey both cold and hot water, whereas HDPE traditionally had limitations with hot water.

All polyethylene and PVC pipes are made from plastic resins derived from fossil fuels, with various synthetic chemicals added to enhance manufacturing and performance in conveying water. Despite their distinct chemical and structural properties, they all begin with ethylene as their base petrochemical. PVC pipes are produced by combining ethylene with chlorine to form ethylene chloride, subsequently converted into vinyl chloride. HDPE pipes involve creating long polymer chains of ethylene with some other hydrocarbons, while PEX pipes use ethylene polymers with enhanced chemical bonding for improved performance.

Research has documented chemical releases from polyethylene-based plastic pipes, as well as PVC pipes. Notably, HDPE pipes release 2,4-di-tert-butyl-phenol (2,4-DTBP), a potential endocrine disruptor and a byproduct of an antioxidant added during manufacturing to enhance pipe performance and longevity. Water conveyed through HDPE pipes may also contain various organic chemicals, including cancer-causing benzene.

This overview provides essential insights into plastic water pipes, theirs types, and chemical considerations.

A TOXIC STEW: Polyvinyl Chloride (PVC) and Chlorinated Polyvinyl Chloride (CPVC) Pipes.

PVC Pipe Manufacturing Process:

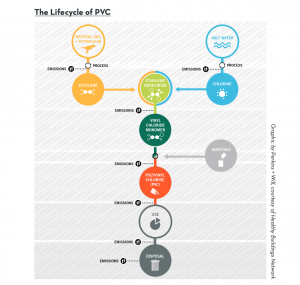

The production of PVC pipes involves a multistep process that employs toxic chemicals at each stage. In the United States, the manufacturing process starts with the generation of chlorine gas, which is then combined with ethylene to produce ethylene dichloride, a probable carcinogen, according to the EPA. Ethylene dichloride is further subjected to high-temperature conversion to vinyl chloride, a known human carcinogen and the essential building block of PVC resin.

Manufacturers introduce chemical catalysts and additional additives to vinyl chloride to transform individual molecules into long chains or polymers of PVC resin, usually in pellet form. Downstream manufacturers heat and shape PVC pellets into rigid pipes, incorporating further chemicals like organotins to enhance product performance.

Some of these chemicals have been linked to reproductive, developmental, hormonal, nervous, and immune system effects, as well as kidney and liver damage, and even cancer. Research indicates that these chemicals can potentially leach from the pipes into drinking water, although the health implications are not thoroughly understood.

This information highlights the chemical complexities and potential health concerns associated with the manufacturing of PVC pipes.

HOW IS DRINKING WATER QUALITY REGULATED?

U.S. EPA Drinking Water Standards

The EPA, under the Safe Drinking Water Act, is entrusted with establishing legal limits, known as maximum contaminant levels (MCLs), for chemical and biological pollutants in public drinking water systems to safeguard public health. States can implement their own standards, provided they are as stringent as the EPA’s.

However, these standards don’t always apply to chemicals that may leach into tap water from plastic pipes since the EPA regulates water quality at the distribution system’s entry point, not at the tap. Testing mainly occurs before water reaches service lines and is often conducted independently.

While the EPA has set MCLs for around 100 contaminants, including 65 chemicals, there are no legal standards for most of the 350,000 chemicals used today. The EPA recently proposed new standards for certain substances (PFAS) but lags behind in chemical regulation compared to other nations.

The rule-setting process has become contentious, prompting the EPA to adopt more voluntary measures like health advisories. These advisories describe contaminant concentrations that don’t pose health risks and assist authorities and water managers.

This highlights the complex landscape of drinking water quality regulation in the U.S., particularly concerning chemicals from plastic pipes.

Pipe Construction Standards and Ethical Concerns

The EPA relies on standards developed by NSF International to ensure the safety of drinking water pipes. The NSF/ANSI 6121 standard establishes minimum requirements for chemicals leaching from pipes, linings, and fittings into drinking water. Pipe manufacturers participate in a certification program run by NSF International, ensuring their pipes meet these standards. NSF certification is commonly required by state health departments and plumbing codes for drinking water infrastructure.

However, concerns arise due to the influence of pipe manufacturers in the standard-setting process. Manufacturers contribute financially to the certification program and participate in committees setting standards. While the final approval rests with NSF International’s Council of Public Health Consultants, which excludes product manufacturers, the industry’s influence raises questions about balanced representation.

In the past, ethics charges were raised against NSF International for forming a for-profit partnership while leading the development of new plumbing standards. Experts expressed concerns about conflicts of interest, calling for the termination of such partnerships. The issue highlighted potential conflicts between public health and commercial interests in setting pipe construction standards.

Balanced representation and transparent, ethically sound procedures are essential for setting testing and certification protocols to ensure health standards are upheld in the construction of drinking water pipes. The balance between public health and profit interests remains a key concern in the development of these standards.

Testing and Certification of Water Pipes

The certification process for water pipe manufacturers, overseen by NSF International, faces scrutiny from researchers who question its soundness. Manufacturers pay NSF International to test and certify their products, ensuring they don’t leach chemicals above the NSF/ANSI 61 standard limits. This process involves annual product testing, facility audits, and biannual inspections of certified production facilities.

Testing conducted by NSF International includes assessments of volatile organic compounds (VOCs), phenolics, vinyl chloride monomers, and metals, among other compounds. Researchers are concerned that the testing period is relatively short (around 20 days), which may not capture longer-term exposure risks associated with chemical leaching.

PVC pipes, in particular, pose challenges due to their dense and rigid structure, resulting in slower leaching rates than other plastics. Variability in chemical leaching from pipes is another issue. Manufacturers may not have complete control over batch consistency, raising concerns about the representativeness of industry-sponsored pre-market testing protocols.

Researchers argue for greater transparency in the certification process, urging NSF International to publish contaminant migration and concentration data for each certified product while safeguarding proprietary information. The ability to access this data would empower water utilities to make informed choices, and researchers could focus on potential health issues related to plastic pipes. However, NSF International currently does not share its testing database with the public, nor does it publish failure rates.

Overall, researchers contend that revisions are needed to align ANSI/NSF Standard 61 with the evolving demands of the U.S. regulatory drinking water environment.

Private Standard Setting for Drinking Water Products

Critics raise concerns about the practice of delegating the setting of standards for products that come into contact with drinking water to private, third-party organizations. Such standards, like NSF/ANSI 61, lack the same level of accountability and public transparency as those established by regulatory agencies with enforcement authority, such as the EPA.

While the EPA’s process for setting drinking water quality standards has its own flaws and potential industry influence, advocates argue that they have more confidence in standard setting by the EPA than by third-party organizations. The EPA tends to engage a broader range of environmental and health groups to ensure a more balanced conversation.

Notably, EPA representatives sit on NSF International’s Health Advisory Board, which collaborates with industry and academic toxicologists in developing third-party standards for unregulated chemicals. While this collaboration is not inherently negative, advocates prefer standards with regulatory authority set through a more public process, as recently done with PFAS.

Terry Collins, a professor of Green Chemistry at Carnegie Mellon University, expresses skepticism about NSF International’s efficacy, particularly in addressing endocrine-disrupting chemicals. He questions how NSF International can provide trustworthy testing and certification for products like PVC piping when it does not appear to recognize endocrine-disrupting chemicals as significant threats to public health.

The private nature of standard setting by third-party organizations raises concerns about transparency, accountability, and the thorough consideration of public health risks.

Who is NSF INTERNATIONAL?

NSF International was founded in 1944 in Ann Arbor, Michigan, to help standardize sanitation and food safety at a time when there were no protections in the U.S. Since then, NSF International has become a global institution, creating 140 active voluntary standards and independent testing protocols, and offering services in more than 170 countries. Though this organization is classified as a nonprofit, NSF International’s board of directors is tilted toward industry. Five of its 10 members are affiliated with companies including McDonald’s, Johnson & Johnson, and Weirton Steel. Notably, there are no toxicologists on the board. Two members are affiliated with public health schools, though one has a history of thwarting regulations that protect the public. Dr. John D. Graham, now dean of the O’Neill School of Public and Environmental Affairs at Indiana University, served as administrator for the Office of Information and Regulatory Affairs at the Office of Management and Budget (OMB) under President George W. Bush. OMB was instrumental in carrying out the Bush administration’s antiregulatory agenda while Dr. Graham served as administrator.